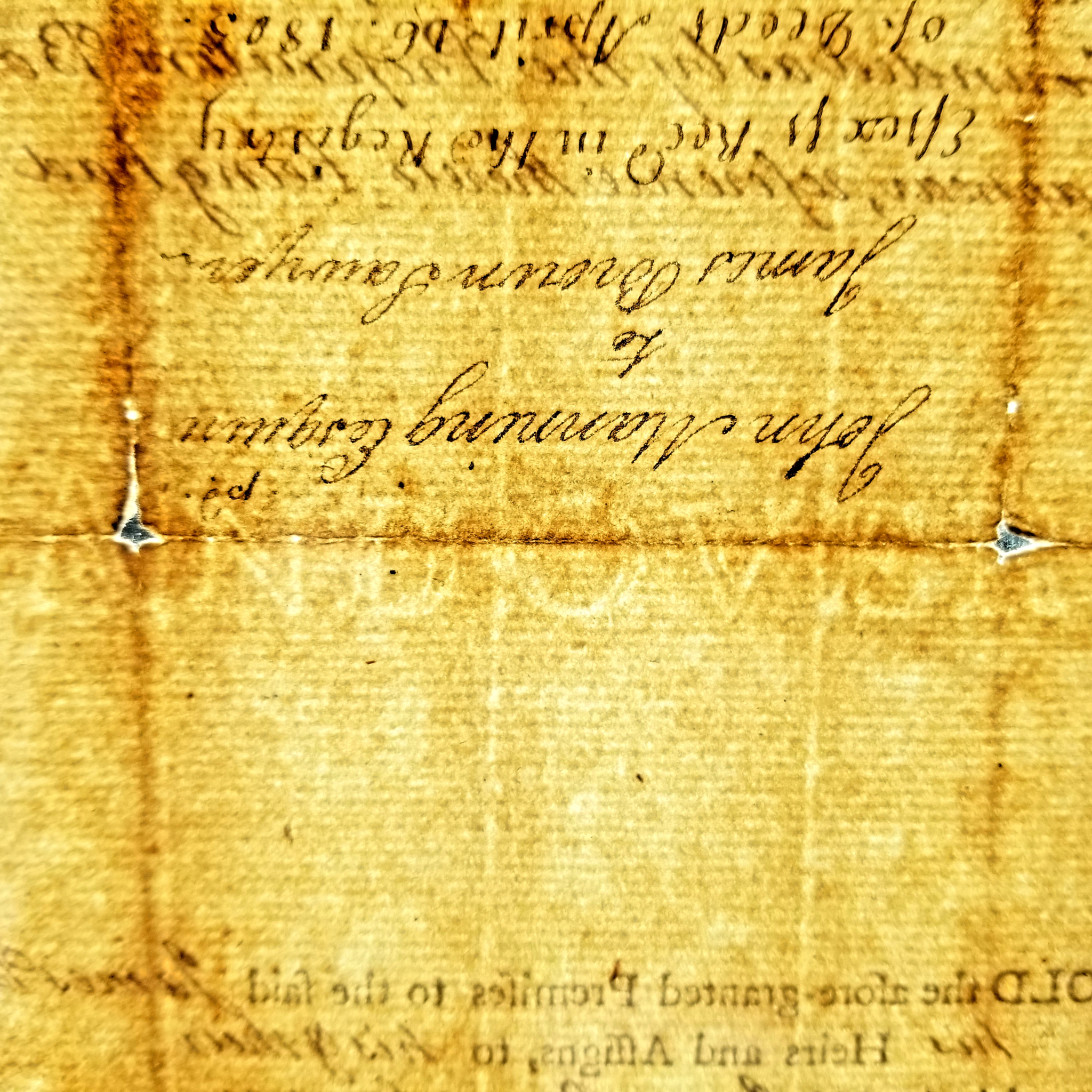

When held up to the light, this deed from 1805 reveals the watermark “Andover!”

The paper was manufactured at Samuel Phillips Jr.’s (1752-1802) mill on the Shawsheen River. He began operations in 1775 producing gunpowder for the Continental Army. George Washington apparently disliked it, and after a series of deadly accidents, Phillips gradually substituted it for papermaking.

It, too, had its issues at first, but proved to be a successful venture. Among his clientele were the State printers, in no small part due to his extensive connections to and involvement in the state government. He was elected lieutenant governor in 1801, but died just a year later.

Phillips’ son John continued the business until 1820, not long after which it became part of Abraham Marland’s cotton mill. No parts of the paper mill survive, but mill buildings on the site dating as far back as the 1830’s remain, repurposed as apartment complexes.

Samuel Phillips wrote the following describing his paper mill:

“A building occupied as a Paper Mill, 36 by 32 feet, with two vats upon the ground floor, which have a Cast Iron pot in each of them, sunk into Brick chimneys, for heating the vats. The first floor has two-engines for beating-stuff, a room for dressing rags, with a brick chimney and fire place, also two other rooms for rags. The second floor is occupied for a Rag ware-house.

“Another building connected to the mill by a covered passage way of 20 ft. long, used for drying and keeping paper before finished, 20 by 24 feet, at the end next the mill ; a part of the drying-house is taken off for a finishing room, 27 by 24 feet, in which is a cast-iron stove used in the winter season…No other building near on the same side of the river. A Grist Mill upon the opposite side of the river, at about 140 feet distance.”

Phillips and his contemporaries used a traditional, handmade paper-making process, the product of which is known as “laid” paper. It starts with the production of pulp by cutting, washing, and heating cotton, linen, or other fibers and mixing it with water in large vats. The pulp is then filtered out of the vats with screened molds and left to dry. Laid paper is identified by the so-called “chain lines” left by the screen. Below is a video recreating the process from the University of Iowa:

Originally published on HistoryBuzz.

Bibliography

Sarah Loring Bailey, Historical Sketches of Andover (Comprising the Present Towns of North Andover and Andover), Massachusetts (Boston: Houghton, Mifflin and Company, 1880), 580-585, https://archive.org/details/historicalsketch00bail.